SAI SURFACE COATING TECHNOLOGIES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SAI SURFACE COATING TECHNOLOGIES

Laser Cladding And Hardening Processes

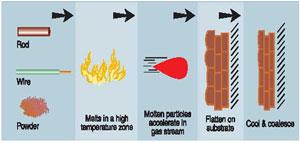

Laser cladding process utilizes a laser source to create a melt pool of the base material and cladding material is introduced into this melt pool in powder form. The energy of the laser melts the cladding material also to form alloying zone between base material and clad material resulting to a metallurgical bonding with good control on required dilution rates.

Laser hardening process is environmental friendly process which will produce very effective hardening layer compare to conventional hardening processes.

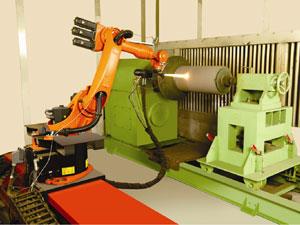

Laser cladding & Hardening Facility at SSCT:

ADVANTAGES OF LASER CLADDING PROCESS:

1. Lower dilution levels

2. Metallurgical Bond

3. Minimal heat effected Zone

4. Minimal part distortion

5. Reduced post processing

6. Highly repeatable process

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.